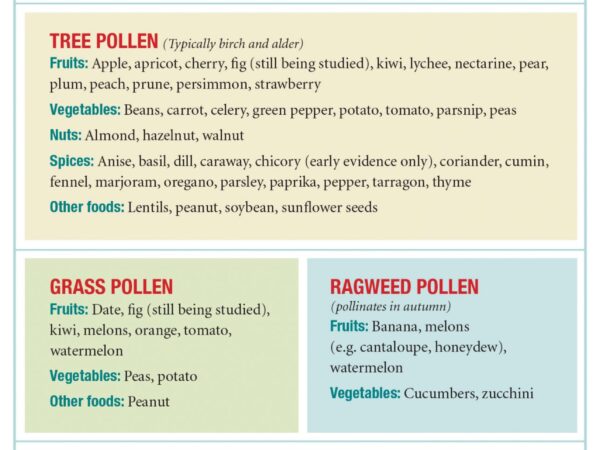

Nutritionist appointments offer valuable opportunities to receive personalized guidance and support for achieving your health goals. By taking proactive steps to prepare for these appointments ….

When it comes to pursuing a career in interior design, there are many different types of courses available to help you achieve your goals. The ….

Creating a captivating presentation requires careful attention to design elements to ensure that your message is effectively communicated and your audience remains engaged. However, there ….

The kitchen stands as the heartbeat of every home, where culinary creations come to life and memories are forged around the dinner table. In this ….

In the world of healthcare, women’s health stands as a unique and intricate field and gynecologist clinic in Dubai plays a crucial role in safeguarding ….

The path to unlocking your full potential begins with daily stretches. This simple, yet powerful practice goes beyond the realm of physical flexibility. It extends ….

Cybersecurity is a paramount concern in today’s digital landscape, and it extends beyond software solutions. Hardware plays a crucial role in fortifying digital defenses, protecting ….

In an era where environmental sustainability is paramount, one area that often goes overlooked is printing. Traditional printing methods can have a significant impact on ….

Inclusive education, which promotes diversity and embraces all students, regardless of their backgrounds or abilities, is a core value in many private schools. These institutions ….

Metal fabrication is an indispensable industry, shaping the very foundation of modern infrastructure, manufacturing, and construction. However, it is often perceived as a complex and ….

Maintaining a nutritious diet in the midst of a busy lifestyle can be challenging, but it’s not impossible. With the right strategies and some healthy ….

Embarking on an Atlantis helicopter tour is an exciting adventure that offers a unique perspective of the world from above. To ensure a smooth and ….

Safes come in various types, each designed to cater to specific security needs and requirements. Understanding the different types of safes can help you choose ….

Taking a helicopter ride can be an exciting and unforgettable experience, but it’s important to be prepared to ensure a safe and enjoyable flight. This ….

Sustainability is becoming an increasingly important factor in the construction industry, and GRC companies in Dubai are playing a critical role in helping to achieve ….